Repair: Difference between revisions

Jump to navigation

Jump to search

Content deleted Content added

No edit summary |

No edit summary |

||

| Line 28: | Line 28: | ||

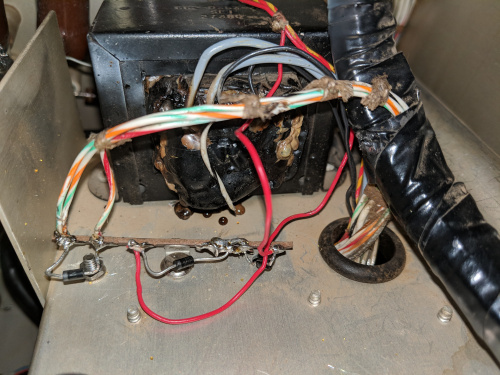

[[File:30s1_decrepit_T202.jpg|500px|thumb|center|Filament transfomer T202 had broken leads!]] |

[[File:30s1_decrepit_T202.jpg|500px|thumb|center|Filament transfomer T202 had broken leads!]] |

||

[[Dealing with the Overheated and Cracked R232]] |

|||

[[Dealing with the RF Output]] |

|||

[[BIAS Transformer T203, and Associated Circuitry]] |

|||

[[Screen Supply Overhaul]] |

|||

[[12V Safety and Control]] |

|||

[[Primary AC Wiring]] |

|||

[[Dials]] |

|||

[[Power Supply & Lower Compartment]] |

|||

Revision as of 22:03, 1 June 2020

I printed the schematics, figured out how to remove the Relay Shelf, and began:

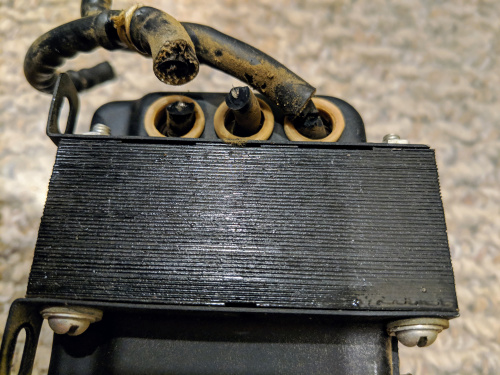

- Bias Transformer T203 was utterly toasted... burned and bubbled. Fortunately Peter Dahl / Hammond offer a top-quality replacement - Whew! Nearby components and the wiring-harness appeared miraculously undamaged!

- Bias rectifiers had been changed to silicon diodes, mounted on a terminal-strip. However, the terminal-strip was bent over, shorting at least one (perhaps two) leads to the chassis.

- In a similar vein on the underside of the Relay Shelf, Bias divider resistor R218 was bent to touch the chassis

- Next to this bent/touching resistor, I then saw the cracked-and-broken 10-ohm R232 (limits screen-supply inrush current).

- And, the RF output connector had been changed from the N-flanged original, to a loose-and-sloppy SO-239 barrel (featuring mangled threads which prevented tightening).

- Time-delay thermal relay K202 was only 35-seconds, not 3-minutes as Collins designed (to ensure V101's cathode is properly heated before use).

- Rectifier-filament transformer T202 had cracked-and-broken secondary leads. Because this amplifier had replacment solid-state HV rectifiers, I decided to simply remove the no-longer-needed T202.

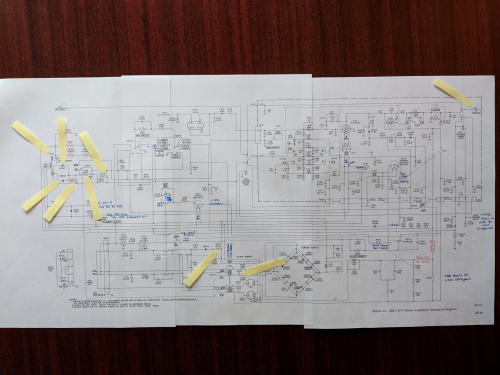

Here is a photo of the taped-up schematic, with my annotations and some flags showing the components I decided to replace:

Beyond these quickly-visible electrical problems, I noted that there were some other changes and physical areas needing my attention too:

- The 3B28 rectifiers have been changed to solid-state modules. These modules were mounted to a thin piece of plywood, and look electrically OK... but it is not a thing of beauty

- The 12AL5 dual-diode ALC rectifier-tube has also been changed to a plug-in solid-state diode. This looked tidy. It functionally implements Collins' Service Bulletin SB-3, Nov 1/69 (space-charge standoff voltage from 12AL5 tube)

- The "TUNING" dial had some rubbed/dissolved printing 'way down at the low-end of the dial. The dial functioned, but I knew this would truly annoy me.

- The "LOADING" dial had cracked and been repaired, with a visible glue-line. The repair was very neatly done, but I would find it a constant aggravation simply knowing it was there.

- The 12V filter-capacitors C211A and C211B (a two-section can) looked sketchy: A previous repair fished up into the internals of the can to effect a connection to one of the caps (!), and a scary bare wire snaked through (grounded/conductive) obstacles from the cap to the circuit. It's possible all this did work, but I'd lose sleep if I ignored this area...

Here's a visual summary:

Dealing with the Overheated and Cracked R232