BIAS Transformer T203, and Associated Circuitry

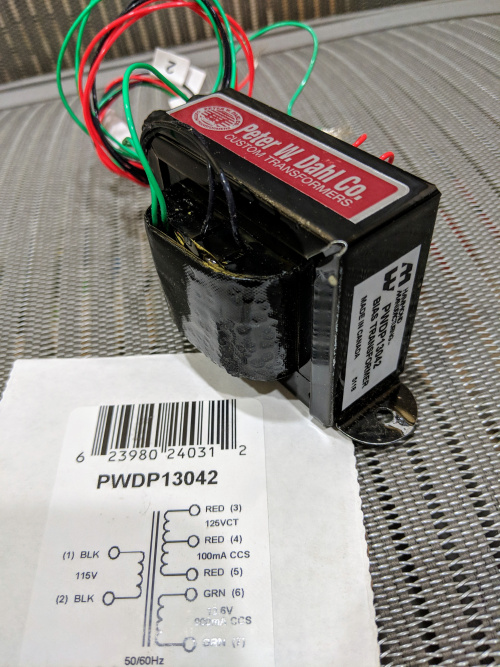

The replacement Peter Dahl transfomer! It took 2-1/2 months from initiating the order, until delivery. I made the actual purchase through Digi-Key, who provided the customer-facing fulfilment for Hammond. The transfomer also includes a 12.6VAC (at 800ma continuous commercial service) winding, which is used for three distinct purposes within the 30S-1:

- the AC voltage from this winding powers the incandescent dial and meter bulbs

- rectified and filtered DC runs through the HV-interlock circuit

- rectified and filtered DC is used to operate the Antenna Relays (when an external short-to-ground occurs - often an Amp T/R relay inside the exciter)

- BIAS Testing

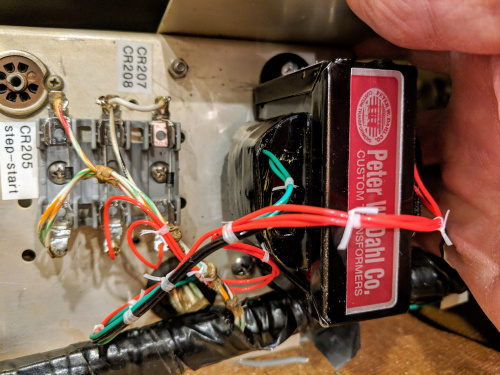

T203 installed, laced and soldered into it's new home!

When I look at the previous T203, especially the type of insulation and the under-chassis un-laced wiring, it makes me wonder if my burned T203 was already a replacement...? Hmmm... I will thoroughly check each and every circuit associated with this transformer, because it seems possible that this BIAS transformer, in this amp, has been an on-going issue. I intend to firmly quash all the problems now!

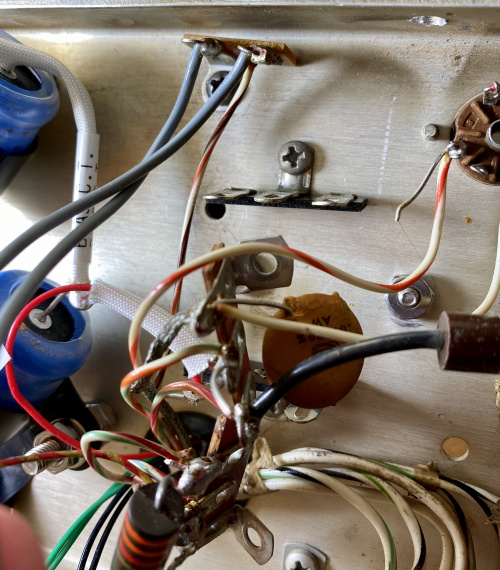

The original selenium rectifiers were long-gone, having been replaced with a terminal-strip and newer silicon diodes. Rather than replace or simply fix what was already there, I wanted to prevent another bent-and-shorted kind of tragedy (if it can happen once...).

I borrowed Collins' own idea from their nearby 12V rectifiers: I bought a triple-fuse mounting block (designed for AGC tubular glass fuses), and mounted my replacement 1N4005 diodes to this fuse-holder. The diode-leads were lightly clinched, then soldered to the fuse-clips, while the circuit connections were made to the holder's solder-tabs.

These diodes aren't going anywhere! And the printed component-labelling may help me (or someone else) in the future.

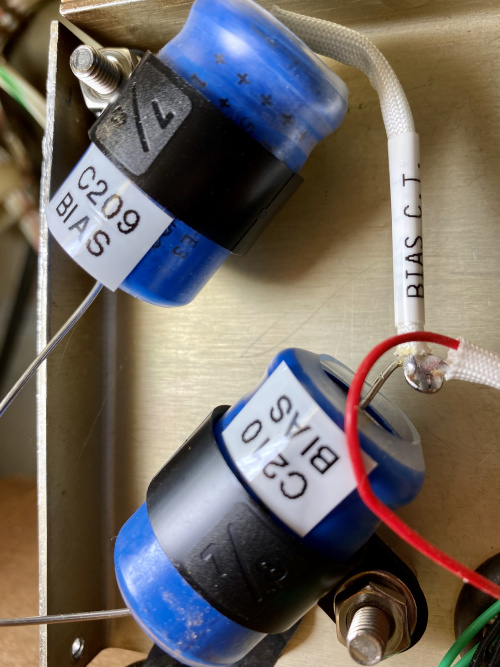

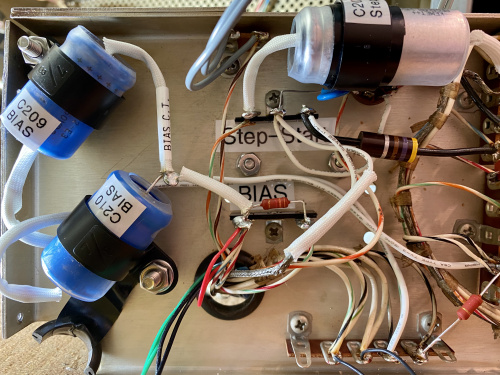

C209 and C210 upgraded, mechanically secured, and labelled A pair of new capacitors - same 50uF, but uprated from 150VDC to 250VDC, working temperature range -20C to +85C. The capacitors are labelled, as is the T203 Bias-Transformer centre-tap connection (I may be the next person helped by this clear labelling!). An additional layer of clear heat-shrink was added to ensure HV sturdiness, and the nylon mounting clamps are spaced a further 8mm off the chassis.

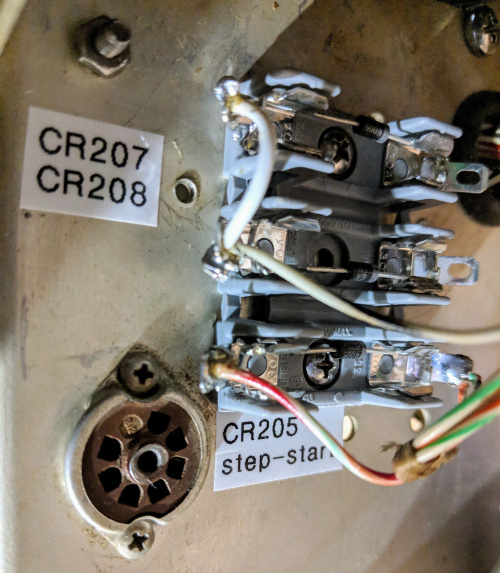

I broke this brittle terminal-strip.

While working underneath the Relay Shelf, I broke a terminal-strip. Unable to find an exact replacement, I opted for two smaller terminal-strips, turned 90-degrees to the original. And, this allowed me to neatly separate the two functions on the original: the Step-Start circuit, and the BIAS connections.

Replacement C203 step-start capacitor, securely mounted.

I replaced C203, making sure it's well-secured, and well-insulated. There should never be a problem of fat-fingers causing future short-circuits! The new C203 is rated at 200VDC, which improves on the original 150VDC rating, especially comforting considering how the incoming AC line-voltage has increased over the decades: designed with 115VAC/230VAC in mind, my current voltage is ~6% higher at 122/244 (just measured it).

Underside of Relay Shelf, now tidied.

Whew! All the parts I indicated on the schematic with yellow arrows have now been replaced - YAY! Now, on to some of the upgrades...

Test-time had arrived. I carefully metered the entire Bias circuit, and didn't like the way the "Bias Adjust" potentiometer contacts were nearly touching the front-panel. A slight bend, and two layers of 600V electrical tape eased my concern. All connections seemed sound, and there were no detectable shorts.

I made up an AC power-cord with alligator-clips, and hooked onto the (not-yet-wired-in) Bias Transformer primary, with the 12V secondary still un-connected and capped-off. This would test the Bias supply only.

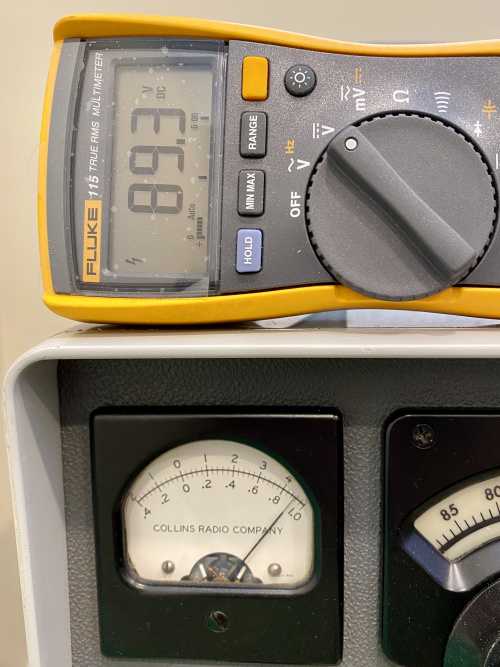

CW (fixed) Bias test

Mode switch in the CW position, internal meter set to "Bias Voltage", my Fluke meter connected to the V101-socket grid-connection and the common + of C209 and C210. YAY! -90V showing on both meters. And especially ... NO SMOKE

Continuing, I placed the mode-switch in the SSB postion, and found I could easily adjust the SSB negative bias from about -22V to the CW level of 90V. Having read that I would get the right plate-idle-current with around -55V to -60V bias, I set it to -60V for now. Again, it was nice to see agreement between the Collins internal meter and my Fluke.

This first power-application test was really gratifying, after the long idle and rebuilding periods. And because I believe this was the troublesome circuit that caused my smoke-out, I'm actually elated to see this first section working!