160m Mods: Difference between revisions

No edit summary |

No edit summary |

||

| Line 83: | Line 83: | ||

It is possible to stack blanks on top of an old bakelite template and do two or three at a time, but final filing should be done one at a time. Dimensions are critical in order to assure good contacts. |

It is possible to stack blanks on top of an old bakelite template and do two or three at a time, but final filing should be done one at a time. Dimensions are critical in order to assure good contacts. |

||

[[File: |

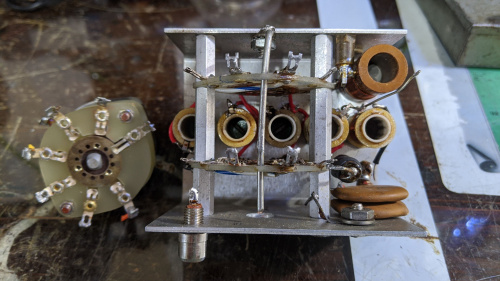

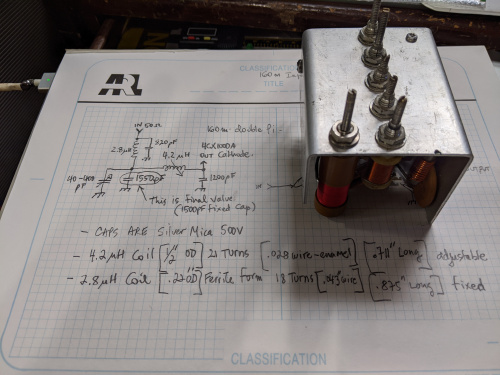

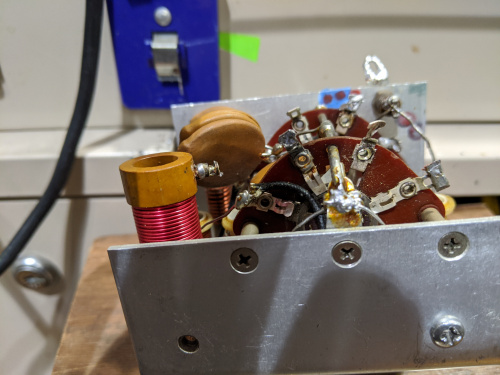

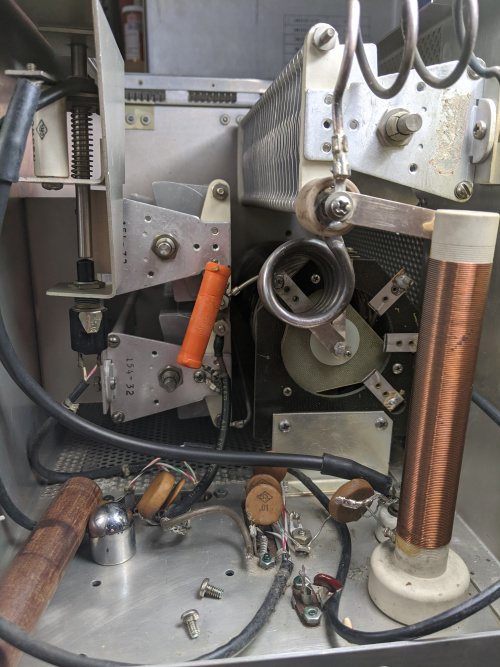

[[File:wafer1.jpg|500px|thumb|center|Fig.1 160m input-Pi circuit and L, C elements]] |

||

Revision as of 23:29, 30 October 2020

160m Mods. The 160m mods involve working on:

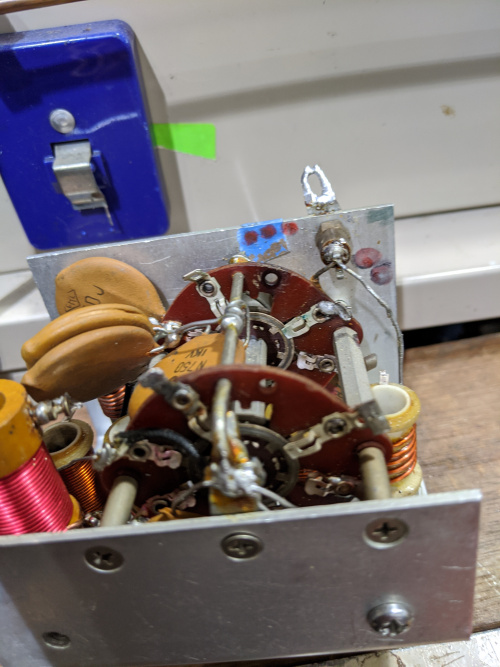

1. the input PI section fig.1-4.

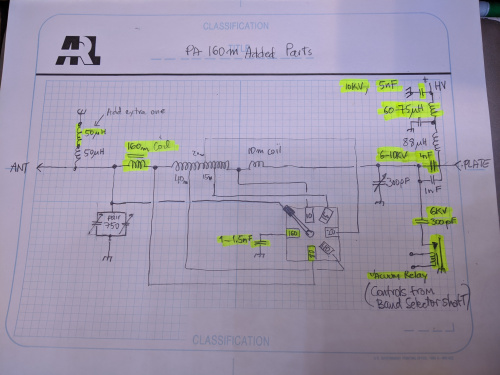

2. the PA output PI section fig. 5-8

3. removing one of the bandswitch stops fig.9

The Caveats: NB. It appears there are two different 30S1 input circuits depending on the age of the 30S-1 amp. The 160m mod is practical only for input circuits using simple wafers with contacts on one side only. If there is a grounding ring in addition to a selector ring then things get rather complicated. This mod does not deal with the double sided grounding wafers for obvious complex fabrication reasons. The wafers used in the 30S-1 are 45 degree type, next to impossible to find. The bakelite material is old and very easy to fracture. Utmost care is necessary to prevent breakage. The alternative is to make new blanks with FR40 board material a time consuming proposition. If you repair old clocks as a hobby you will have no problems ;))

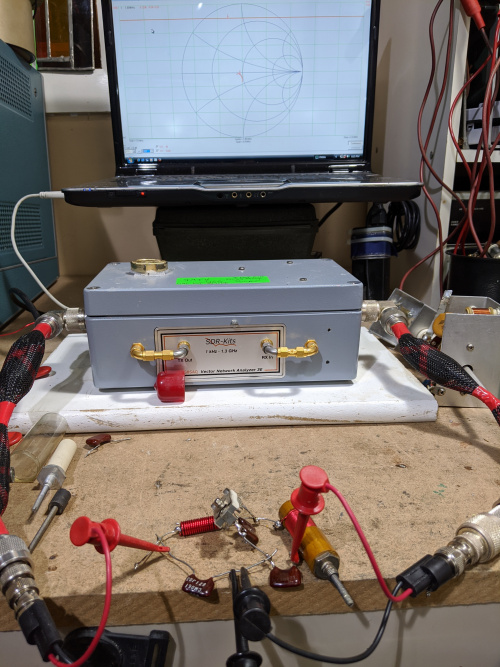

The PA anode choke may have resonances near or on the upper ham bands depending on how you mount the extra 160m choke and what is the total inductance and capacitance. If you hit a resonance at full RF power you will have fireworks in the RF compartment. It's your job to measure the spurious resonances when finished and adjust the 160m choke accordingly.

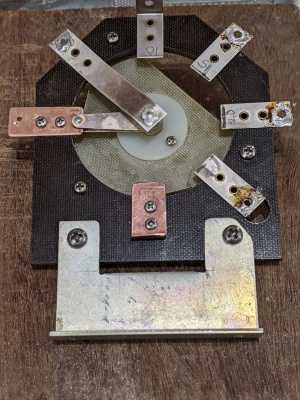

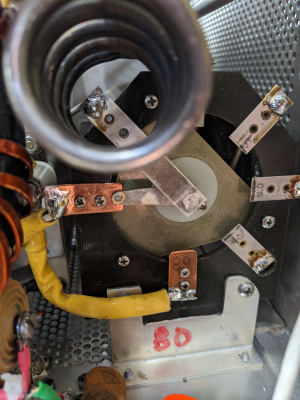

It is possible to instal the 160m tabs without dismounting the input wafers. Do not to use too much pressure when working on the wafers. Use miniature screws and nuts to hold the tabs in place as riveting is not recommended unless the wafers are removed. Notice there are two contacting tabs per wafer. Multimeter wafer are also 45 degree index, but are not interchangeable with the input band wafers.

It's a tight fit inside the input circuit compartment, but there is enough room for the 160m Ls and Cs. Facing the front, the 160m variable coil is mounted to the left side, next to the 80m coil. The fixed coil and SM caps are tucked inside the aluminum frame.

Collins uses 1KV ceramic disk capacitors for the other bands, ideally the 160m capacitors should be 1 KV SM but space is tight. The 500V SMs showed no leakage up to 1.5KV, so should be safe to use with up to 3 to 1 SWR. Alpha 77Sx uses compression silver micas which have higher Q than ceramics.

The 160m C values are 800pf, 1200pf, 1600pF. Start with these values as there could be small adjustments depending on SWR. I had to guess the input Z of the 4CX1000A; it is probably around 50-100 Ohms. There is no problem to match within this 2-1 range. The 160m L values are 4.2microH (adjustable), and 2.8 microH wound on a ferrite rod with leads.

The L, C values were adjusted for min SWR. 160M mods require an extra L and an extra C to cover the bandwidth, same number of elements like the 80m PI circuit.

There is enough room to either accommodate the 160m PA coil made from a single 3" iron powder core or two stacked 2" ones. The inductance range that seems to work is 7.5 to 8.5 microHenries.

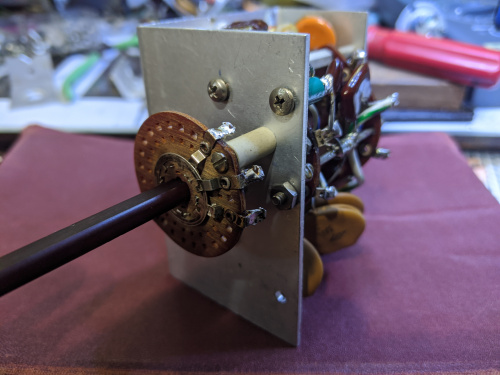

- PA-Wafer. Adding 80m and 160m tabs

In the right figure it appears that the 80m and 160m tabs are connected (yellow sleeve), but they are not.

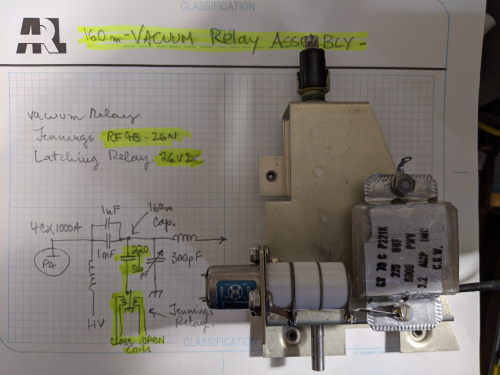

Jennings F4B-26S is a 26V pulsed DC latching relay with two 7 Ohms coils, one coil for turning ON and the other for turning OFF. A pair of 555 timers could be set up, but they require additional power sources. Still investigating a simple relay circuit that converts ON, OFF states to momentary pulsed ones. Suggestions are welcomed.

One of the two band stops is drilled out to yield the 160m position. That's the hole closer to the center shaft. With the RF deck mounted on the PS cabinet, the stop to be drilled out is at ~11:30 o'clock. The other stop at ~6:30 is left alone. In this image the RF deck is laying on its left side. The 30S-1 band knob will point downwards for 160m.

Make sure you reinstall everything correctly and that there are no shorts. It is advisable to take pictures during the dismantling process of the various PA parts. Do not override the safety switches and be safe. You already know Killer Potentials are present.

WAFER FABRICATION DETAILS.

To replace all 30S-1 wafers and add 160m, five wafers are needed. Two for the multi-meter, two for the input Pi circuits, and a fifth one to switch the 160m PA vacuum relays.

Either FR4 or FB PCB .66" thick can be used. Any copper on the board is removed by using etching solutions.

A broken bakelite wafer is used as a blank. While years ago I was able to get several wafer blanks made by local PCB processing company, that opportunity does not appear likely again because the job is too small and the tooling cost is not worth it. I now make blanks the old fashion way, by using hand tools, files, coping saws and drills.

It is necessary to have access to some surplus 30 degree index wafers and cannibalize them for the center disk and contacts. I got most of mine at hamfests. Ebay may be another source. However there are lot of different wafer sizes, type of contacts and center disks dimensions (thickness and diameter), so careful searches knowing the right dimensions are a must, or time and money is wasted.

A little practice with riveting is recommended before starting and having the right tools.

It is possible to stack blanks on top of an old bakelite template and do two or three at a time, but final filing should be done one at a time. Dimensions are critical in order to assure good contacts.