Operation: Difference between revisions

| Line 38: | Line 38: | ||

The general principle: start with reduced-drive, then workg up to your desired power-level. Never let things get out-of-hand. For the 30s-1 and the 4CX1000A tube, stick to 0 grid-current! Normally, with a good tube, you will neither need it, nor have it; decrepit tubes may show notable grid-current which will seal their fate :-( |

The general principle: start with reduced-drive, then workg up to your desired power-level. Never let things get out-of-hand. For the 30s-1 and the 4CX1000A tube, stick to 0 grid-current! Normally, with a good tube, you will neither need it, nor have it; decrepit tubes may show notable grid-current which will seal their fate :-( |

||

<b>Plate Dip Method</b> |

<b>Plate Dip Method</b><br> |

||

This is always a good, safe method: |

This is always a good, safe method: |

||

<b>LOADING</b> control CCW (low numbers) |

<ul><li><b>LOADING</b> control CCW (low numbers)</li> |

||

<b>MODE</b> in SSB (far-right toggle switch UP) |

<li><b>MODE</b> in SSB (far-right toggle switch UP)</li> |

||

<b>TRANSMIT:</b> No-drive BIAS should give you 200mA idle Plate Current (maybe 250mA if you use a 4CX1500B and want improved linearity). |

<li><b>TRANSMIT:</b> No-drive BIAS should give you 200mA idle Plate Current (maybe 250mA if you use a 4CX1500B and want improved linearity).</li> |

||

<b>DRIVE</b> increase slightly to give some Plate Current, then quickly |

<li><b>DRIVE</b> increase slightly to give some Plate Current, then quickly</li> |

||

<b>TUNE</b> knob adjusted to give a Plate Current dip (resonance) |

<li><b>TUNE</b> knob adjusted to give a Plate Current dip (resonance)</li> |

||

<b>DRIVE & LOADING</b> are alternately increased, the <b>Re-DIP</b> |

<li><b>DRIVE & LOADING</b> are alternately increased, the <b>Re-DIP</b></li> |

||

<b>Plate Current</b> held to 300mA - 350mA, which is about the rated 1kW DC input it was designed for. You're done when you hit this desired Plate Current. If you have a Wattmeter, it should have a healthy reading (in the neighbourhood of 600W, maybe) and it should have shown approximately a peaking as you dip the plate. |

<li><b>Plate Current</b> held to 300mA - 350mA, which is about the rated 1kW DC input it was designed for. You're done when you hit this desired Plate Current. If you have a Wattmeter, it should have a healthy reading (in the neighbourhood of 600W, maybe) and it should have shown approximately a peaking as you dip the plate.</li></ul> |

||

This same method works with transmitters which use tube-finals. For several decades, I used Heathkit, Yaesu and other radios from the 60's and 70's and this was the manufacturer's described method of tuning too. |

This same method works with transmitters which use tube-finals. For several decades, I used Heathkit, Yaesu and other radios from the 60's and 70's and this was the manufacturer's described method of tuning too. |

||

Revision as of 18:59, 28 November 2020

Dayton Blower Sound Level

Here is a video-clip to provide an idea of the blower-noise after changing the motor to the 3,000rpm Dayton 4M093E. For context I provide a brief introduction with my voice, and I have my receiver on. I used the NIOSH iOS app to obtain these measurements, before we get to the video:

- 30S-1 with Dayton 3,000rpm motor change: 59 dB(A) 1-meter directly in front

- Listening to HF Radio, SSB voice: 65 dB(A) for my preferred Sound Level

- My living-room is a blissful 36 dB(A)

Video - Dayton Blower Start-up and Sound Level

Dial Lights After Warm-Up

The 30S-1 amplifier was designed with a 3-min delay before allowing High Voltage on the tube - the Eimac datasheet specifies at least this long. Mine is closer to 2-1/2 minutes, so I must pause before pushing the "ON" button. To let me know when this time-delay has completed, I re-wired my dial-lights to the DC circuit which is down-wind of the thermal delay-timer; the dial-lights will only turn on after the time-delay.

- remove the hot lead from lamp socket DS201

- Add a new lead from DS201 to the white-red-orange-green wire at the rear of the HV "OFF" switch, S208 (either contact)

Here is a 10-second video clip showing the dial-lights illuminating, after the time-delay:

Video - Dial Lights after Warm-Up

Spares and Servicing

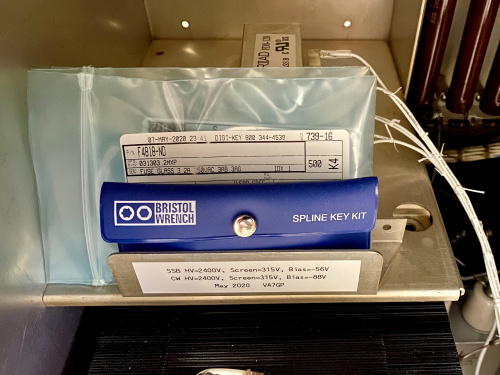

I use the Power Supply Shelf for storing 2 sets of spare fuses, and a set of Bristol wrenches:

Contests: SSB and CW

I (casually!) entered Field Day 2020, and gave my newly-renovated 30S-1 a weekend shake-down run. To jump between modes, I left the 30S-1 in "SSB" mode - this meant I always had idling-current, and did not operate the amp in Class C for CW. The penalty: higher heat dissipation. The benefit: one less thing to think about.

Tuning

How often? How to tune?

Tuning And Frequency Changes

My personal answer to "How Often" revolves around changes in frequency: I feel I must retune if I change by 50kHz on 20-15-10, and every ~25kHz on 40-80. Beware - I view these as maximum (contest) changes in frequency, where the amp will become a bit stressed (higher dissipation), but not unduly. If things are slow, I may re-tweak much more-often... maybe every few kHz :-)

There is a second answer too, involving changes in power, but it's less-common. If the power-level is changed - 25% might be good guidance - then the (Plate Voltage) / (Plate Current) impedance changes, and the Pi-output network will need adjustment too - if only for the proper impedance transformation, supposing resonance isn't greatly affected.

How To Tune

<ul

The general principle: start with reduced-drive, then workg up to your desired power-level. Never let things get out-of-hand. For the 30s-1 and the 4CX1000A tube, stick to 0 grid-current! Normally, with a good tube, you will neither need it, nor have it; decrepit tubes may show notable grid-current which will seal their fate :-(

Plate Dip Method

This is always a good, safe method:

- LOADING control CCW (low numbers)

- MODE in SSB (far-right toggle switch UP)

- TRANSMIT: No-drive BIAS should give you 200mA idle Plate Current (maybe 250mA if you use a 4CX1500B and want improved linearity).

- DRIVE increase slightly to give some Plate Current, then quickly

- TUNE knob adjusted to give a Plate Current dip (resonance)

- DRIVE & LOADING are alternately increased, the Re-DIP

- Plate Current held to 300mA - 350mA, which is about the rated 1kW DC input it was designed for. You're done when you hit this desired Plate Current. If you have a Wattmeter, it should have a healthy reading (in the neighbourhood of 600W, maybe) and it should have shown approximately a peaking as you dip the plate.

This same method works with transmitters which use tube-finals. For several decades, I used Heathkit, Yaesu and other radios from the 60's and 70's and this was the manufacturer's described method of tuning too.