160m Mods: Difference between revisions

No edit summary |

No edit summary |

||

| (53 intermediate revisions by the same user not shown) | |||

| Line 69: | Line 69: | ||

WAFER FABRICATION DETAILS. |

'''WAFER FABRICATION DETAILS'''. |

||

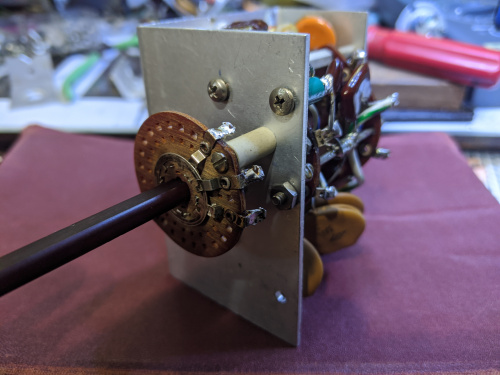

To replace all 30S-1 wafers and add 160m band, a total five wafers are needed. Two for the multi-meter, two for the input Pi circuits, and a fifth one to switch the 160m PA vacuum relays. Note that the multi-meter and Pi-Band wafers are similar 45 degree index but not identical. Also important to note is that the new wafers are based on the older single sided type wafer, not the double sided wafer that shorts out all unused band contacts. That's too complicated a wafer design to implement here. I am not sure why Collins made the change with the later built amps but not all amps short out the unused band circuits. Anyhow I have not noticed any ill effects, although to keep low input SWR some coil adjustments are needed from time to time from the top cover holes depending where in the band you operate. |

To replace all 30S-1 wafers and add 160m band, a total five wafers are needed. Two for the multi-meter, two for the input Pi circuits, and a fifth one to switch the 160m PA vacuum relays. Note that the multi-meter and Pi-Band wafers are similar 45 degree index but not identical. Also important to note is that the new wafers are based on the older single sided type wafer, not the double sided wafer that shorts out all unused band contacts. That's too complicated a wafer design to implement here. I am not sure why Collins made the change with the later built amps but not all amps short out the unused band circuits. Anyhow I have not noticed any ill effects, although to keep low input SWR some coil adjustments are needed from time to time from the top cover holes depending where in the band you operate. |

||

| Line 77: | Line 77: | ||

Either FR4 or FB PCB .66" thick can be used. Any copper on the board is removed by using etching solutions. |

Either FR4 or FB PCB .66" thick can be used. Any copper on the board is removed by using etching solutions. |

||

A broken bakelite wafer is used as a template. While years ago I was able to get several wafer blanks made by a local PCB processing company, that opportunity does not appear possible again because this job is too small and the tooling cost |

A broken bakelite wafer is used as a template. While years ago I was able to get several wafer blanks made by a local PCB processing company, that opportunity does not appear possible again because this job is too small and the tooling cost is not worth it. |

||

If I have to make blanks I do it the old fashion way, by using hand tools, files, coping saws and drills. |

If I have to make blanks I do it the old fashion way, by using hand tools, files, coping saws and drills. |

||

[[File:tools.jpg|500px|thumb|center|Fig.b Assortment of hand tools used to make new wafers]] |

[[File:tools.jpg|500px|thumb|center|Fig.b Assortment of hand tools used to make new wafers]] |

||

| Line 84: | Line 84: | ||

It's necessary to have access to some common surplus 30 degree index wafers and cannibalize the center disk and contacts. |

It's necessary to have access to some common surplus 30 degree index wafers and cannibalize the center disk and contacts. |

||

Most of mine were purchased at hamfests, cheap and by the box load. Not so cheap ones are from Ebay. However there are lot of different wafer sizes and types, type of contacts and center disks dimensions (thickness and diameter), so careful searches knowing the right dimensions are a must, or time and money |

Most of mine were purchased at hamfests, cheap and by the box load. Not so cheap ones are from Ebay. However there are lot of different wafer sizes and types, type of contacts and center disks dimensions (thickness and diameter), so careful searches knowing the right dimensions are a must, or time and money are wasted. Good luck in trying to find 45 degree wafers that fit the 30S-1, they simply do not exist anymore. |

||

| ⚫ | |||

It is possible to stack blanks on top of an old bakelite template and do two or three at a time, but final filing should be done one at a time. Dimensions are critical in order to assure good contacts. |

It is possible to stack blanks on top of an old bakelite template and do two or three at a time, but final filing should be done one at a time. Dimensions are critical in order to assure good contacts. |

||

| ⚫ | |||

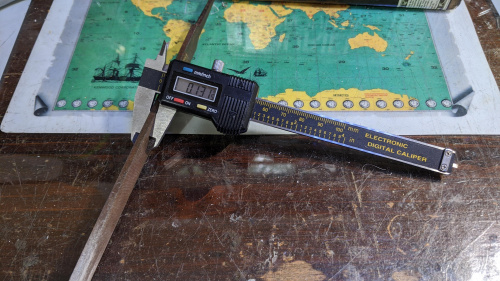

[[File:file.jpg|500px|thumb|center|Fig.e A 0.13" thick file is very useful for shaping the rectangular wafer slots.]] |

[[File:file.jpg|500px|thumb|center|Fig.e A 0.13" thick file is very useful for shaping the rectangular wafer slots.]] |

||

After using a coping saw to create rough wafer slots for seating the contacts, use a 0.13" thick file the contact slots. |

|||

[[File:flaring.jpg|500px|thumb|center|Fig.f Flaring tool to enlarge the center hole.]] |

|||

A flaring tool is great to provide the right size center hole. |

|||

[[File:surpluswafers.jpg|500px|thumb|center|Fig.g Assortment of used wafers to provide new wafer parts]] |

|||

[[File:rivets.jpg|500px|thumb|center|Fig.h Assortment of rivets]] |

|||

There is an option to using relays (auto antenna tuner types) for the input Pi Band circuit instead of using wafers. This is a new project I may implement next for the 30S-1 pending input SWR measurements |

|||

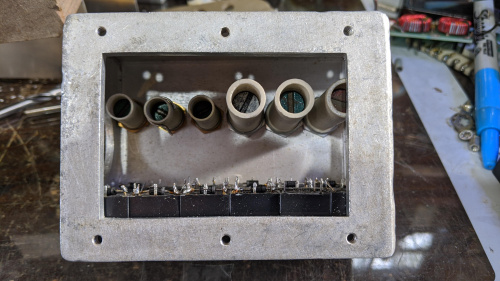

[[File:inputone.jpg|500px|thumb|center|Fig.i Modified Pi-Input Band switching using surplus relays. ]] |

|||

[[File:inputtwo.jpg|500px|thumb|center|Fig.i Modified Pi-Input Band switching in the same location as the original. ]] |

|||

Using relays makes it easy to short the unused input Pi circuits following Collins latest amp design features. |

|||

While I love the 30S-1 enough to spend many hours working on them, I am not a "true-blue" Collins radio collector and I don't mind making amp improvements using modern components that were not available half century ago. |

|||

My other ongoing project is interfacing the 30S-1 to an ANNAN-7000DLE for low IMD performance. This requires a high power directional coupler. |

|||

I welcome feedback and comments. |

|||

73s |

|||

kb3bf@arrl.net |

|||

== TWO PA TUBES FOR THE 30S-1== |

|||

'''Next Topic:''' |

|||

Can The 30S-1 reach full legal limit and still have laminar air flow? |

|||

How about using two PA tubes? |

|||

It is easier said than done. |

|||

At first the idea was proposed by VE3CFK, Chet but I thought it would be a pipe dream with little hope of success (and it may still be so) but I wanted to see if there was enough space, so I made a template based on the existing socket hole and tried to fit it within the available space. While I did this, I could not help thinking that Collins may have allocated enough space for that same reason when they designed and built the 30S-1. |

|||

Luckily I happen to have a spare 30S-1 with some missing parts, allowing me to play with. |

|||

[[File:Template.jpg|500px|thumb|left|template to prepare the cutout]] |

|||

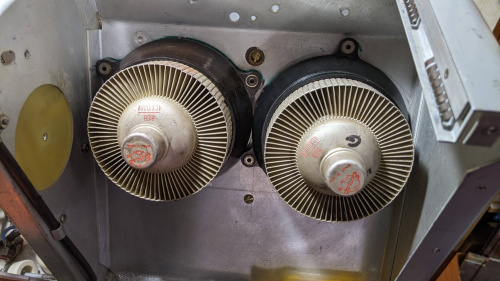

[[File:-3.jpg|500px|thumb|left|It is a tight fit but there is enough room for two tubes]] |

|||

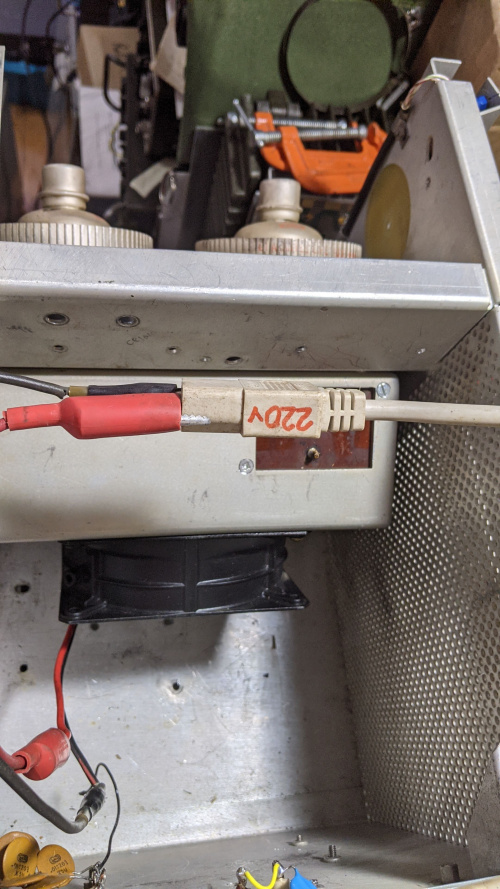

[[File:fan.jpg|500px|thumb|left|An 18W 220V fan mounts on a 8.5" by 5" by 3" custom made chassis, which fits over the 2 PA tube sockets. The sockets had to be rebuilt by replacing the long tabs with ordinary ones. WARNING: Fan wiring is temporary and does not meet NEC, OSHA nor the Canadian Centre for Occupational Health and Safety. ]] |

|||

[[File:twintubes.jpg|500px|thumb|left|Both sockets had to be rebuilt without the long tabs that fit thru the rubber air boot]] |

|||

There is enough room for an extra filament transformer or a single 6V 20A one. |

|||

It is amazing how much progress has been made in fans and how small they now are compared to the original squirrel cage originally installed. |

|||

Grids may have to be wired separately, unless the tubes are perfectly matched; in this case there will be two bias circuits so that each plate idling current can be properly set. This will require also switching PA plate current readings for each tube. |

|||

The cathodes will be wired together, and also the filaments, requiring 6.0V 20A. |

|||

[[File:fitting.jpg|500px|thumb|left|the chassis had to be carefully positioned in order not to interfere with the input Pi circuit]] |

|||

Latest revision as of 14:16, 19 February 2021

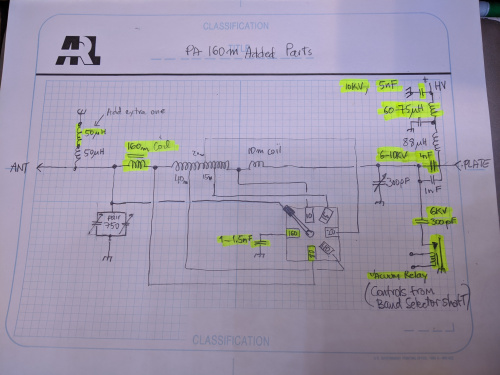

160m Mods. The 160m mods involve working on:

1. the input PI section fig.1-4.

2. the PA output PI section fig. 5-8

3. removing one of the bandswitch stops fig.9

The Caveats: NB. It appears there are two different 30S1 input circuits depending on the age of the 30S-1 amp. The 160m mod is practical only for input circuits using simple wafers with contacts on one side only. If there is a grounding ring in addition to a selector ring then things get rather complicated. This mod does not deal with the double sided grounding wafers for obvious complex fabrication reasons. The wafers used in the 30S-1 are 45 degree type, next to impossible to find. The bakelite material is old and very easy to fracture. Utmost care is necessary to prevent breakage. The alternative is to make new blanks with FR40 board material a time consuming proposition. If you repair old clocks as a hobby you will have no problems ;))

The PA anode choke may have resonances near or on the upper ham bands depending on how you mount the extra 160m choke and what is the total inductance and capacitance. If you hit a resonance at full RF power you will have fireworks in the RF compartment. It's your job to measure the spurious resonances when finished and adjust the 160m choke accordingly.

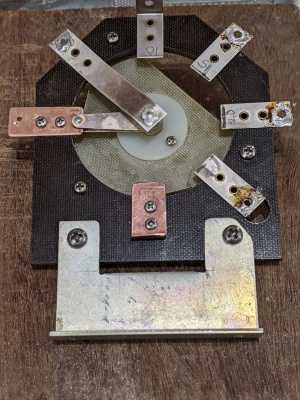

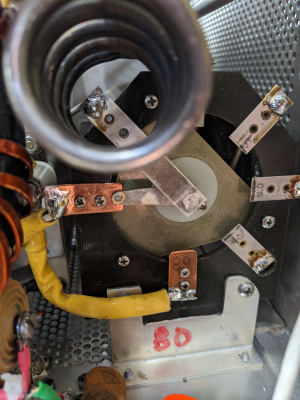

It is possible to instal the 160m tabs without dismounting the input wafers. Do not to use too much pressure when working on the wafers. Use miniature screws and nuts to hold the tabs in place as riveting is not recommended unless the wafers are removed. Notice there are two contacting tabs per wafer. Multimeter wafer are also 45 degree index, but are not interchangeable with the input band wafers.

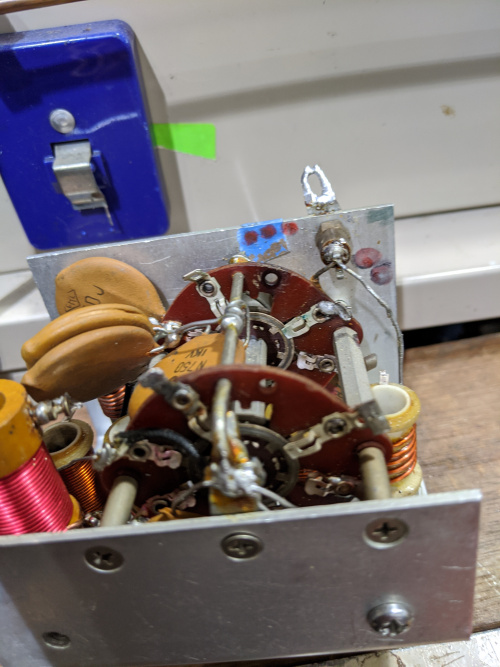

It's a tight fit inside the input circuit compartment, but there is enough room for the 160m Ls and Cs. Facing the front, the 160m variable coil is mounted to the left side, next to the 80m coil. The fixed coil and SM caps are tucked inside the aluminum frame.

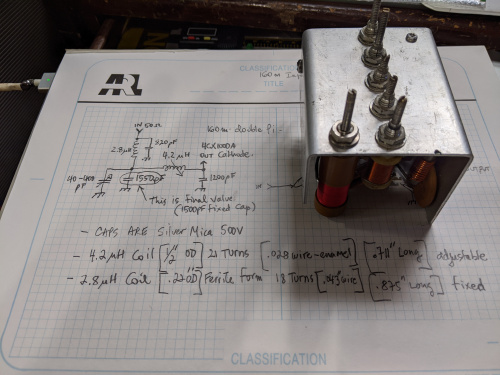

Collins uses 1KV ceramic disk capacitors for the other bands, ideally the 160m capacitors should be 1 KV SM but space is tight. The 500V SMs showed no leakage up to 1.5KV, so should be safe to use with up to 3 to 1 SWR. Alpha 77Sx uses compression silver micas which have higher Q than ceramics.

The 160m C values are 800pf, 1200pf, 1600pF. Start with these values as there could be small adjustments depending on SWR. I had to guess the input Z of the 4CX1000A; it is probably around 50-100 Ohms. There is no problem to match within this 2-1 range. The 160m L values are 4.2microH (adjustable), and 2.8 microH wound on a ferrite rod with leads.

The L, C values were adjusted for min SWR. 160M mods require an extra L and an extra C to cover the bandwidth, same number of elements like the 80m PI circuit.

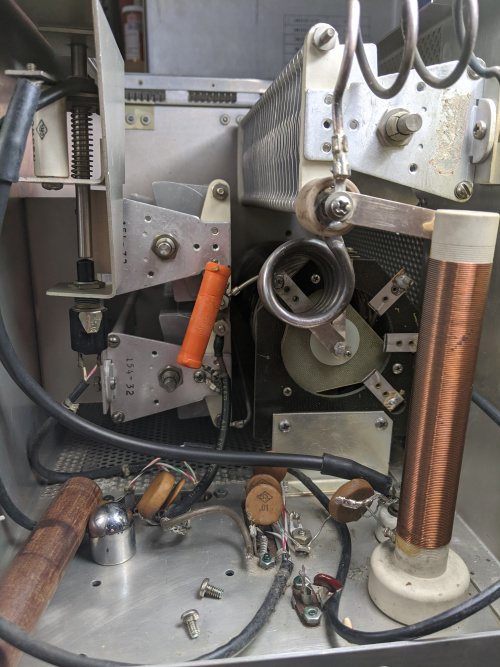

There is enough room to either accommodate the 160m PA coil made from a single 3" iron powder core or two stacked 2" ones. The inductance range that seems to work is 7.5 to 8.5 microHenries.

- PA-Wafer. Adding 80m and 160m tabs

In the right figure it appears that the 80m and 160m tabs are connected (yellow sleeve), but they are not.

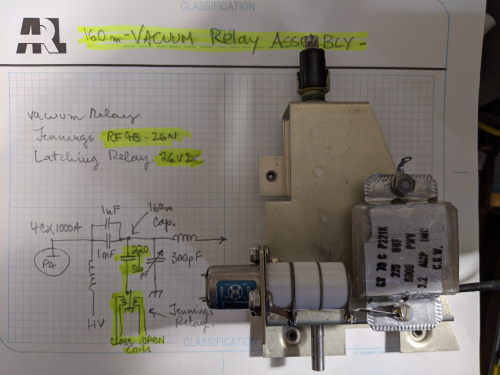

Jennings F4B-26S is a 26V pulsed DC latching relay with two 7 Ohms coils, one coil for turning ON and the other for turning OFF. A pair of 555 timers could be set up, but they require additional power sources. Still investigating a simple relay circuit that converts ON, OFF states to momentary pulsed ones. Suggestions are welcomed.

One of the two band stops is drilled out to yield the 160m position. That's the hole closer to the center shaft. With the RF deck mounted on the PS cabinet, the stop to be drilled out is at ~11:30 o'clock. The other stop at ~6:30 is left alone. In this image the RF deck is laying on its left side. The 30S-1 band knob will point downwards for 160m.

Make sure you reinstall everything correctly and that there are no shorts. It is advisable to take pictures during the dismantling process of the various PA parts. Do not override the safety switches and be safe. You already know Killer Potentials are present.

WAFER FABRICATION DETAILS.

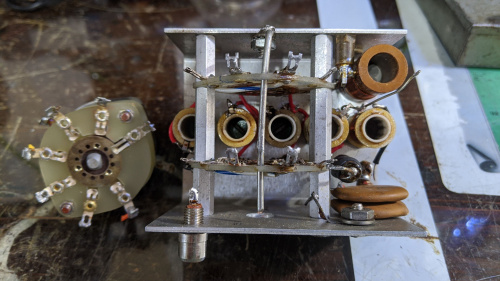

To replace all 30S-1 wafers and add 160m band, a total five wafers are needed. Two for the multi-meter, two for the input Pi circuits, and a fifth one to switch the 160m PA vacuum relays. Note that the multi-meter and Pi-Band wafers are similar 45 degree index but not identical. Also important to note is that the new wafers are based on the older single sided type wafer, not the double sided wafer that shorts out all unused band contacts. That's too complicated a wafer design to implement here. I am not sure why Collins made the change with the later built amps but not all amps short out the unused band circuits. Anyhow I have not noticed any ill effects, although to keep low input SWR some coil adjustments are needed from time to time from the top cover holes depending where in the band you operate.

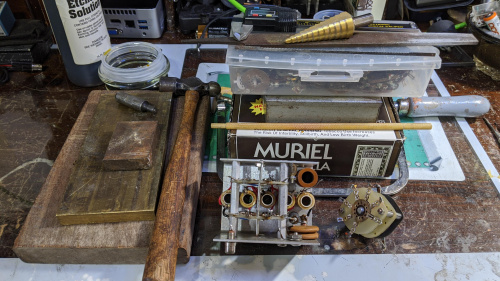

Either FR4 or FB PCB .66" thick can be used. Any copper on the board is removed by using etching solutions.

A broken bakelite wafer is used as a template. While years ago I was able to get several wafer blanks made by a local PCB processing company, that opportunity does not appear possible again because this job is too small and the tooling cost is not worth it. If I have to make blanks I do it the old fashion way, by using hand tools, files, coping saws and drills.

It's necessary to have access to some common surplus 30 degree index wafers and cannibalize the center disk and contacts. Most of mine were purchased at hamfests, cheap and by the box load. Not so cheap ones are from Ebay. However there are lot of different wafer sizes and types, type of contacts and center disks dimensions (thickness and diameter), so careful searches knowing the right dimensions are a must, or time and money are wasted. Good luck in trying to find 45 degree wafers that fit the 30S-1, they simply do not exist anymore.

It is possible to stack blanks on top of an old bakelite template and do two or three at a time, but final filing should be done one at a time. Dimensions are critical in order to assure good contacts.

After using a coping saw to create rough wafer slots for seating the contacts, use a 0.13" thick file the contact slots.

A flaring tool is great to provide the right size center hole.

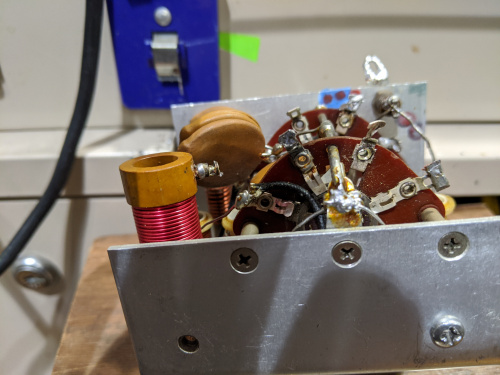

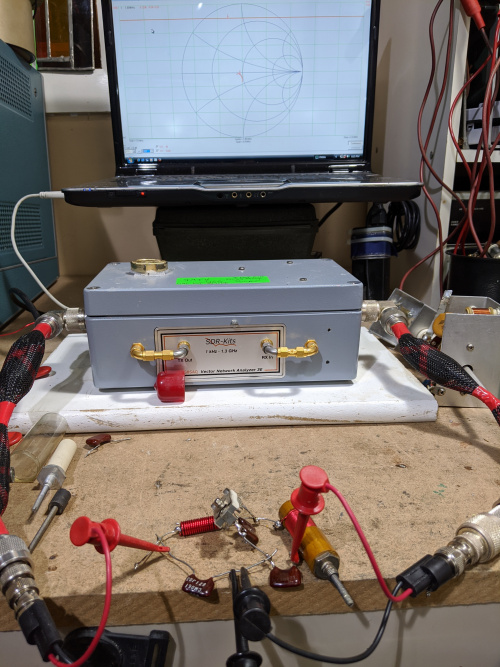

There is an option to using relays (auto antenna tuner types) for the input Pi Band circuit instead of using wafers. This is a new project I may implement next for the 30S-1 pending input SWR measurements

Using relays makes it easy to short the unused input Pi circuits following Collins latest amp design features.

While I love the 30S-1 enough to spend many hours working on them, I am not a "true-blue" Collins radio collector and I don't mind making amp improvements using modern components that were not available half century ago.

My other ongoing project is interfacing the 30S-1 to an ANNAN-7000DLE for low IMD performance. This requires a high power directional coupler.

I welcome feedback and comments. 73s

kb3bf@arrl.net

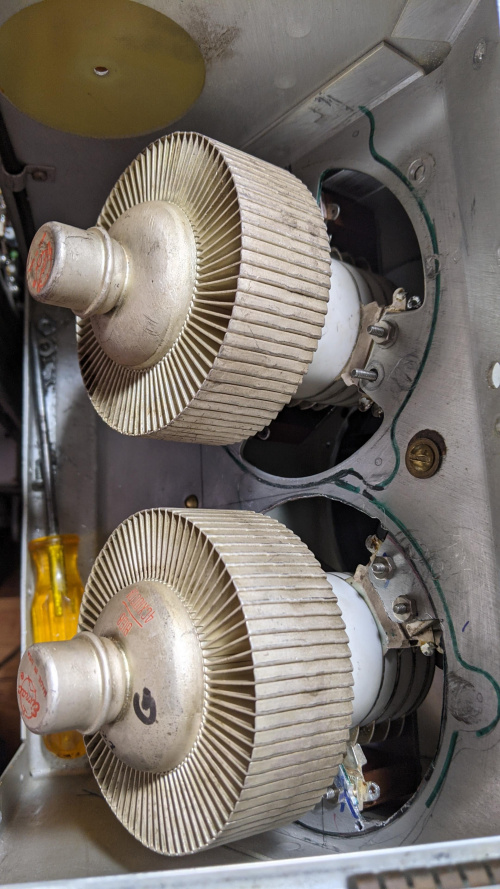

TWO PA TUBES FOR THE 30S-1

Next Topic: Can The 30S-1 reach full legal limit and still have laminar air flow?

How about using two PA tubes?

It is easier said than done. At first the idea was proposed by VE3CFK, Chet but I thought it would be a pipe dream with little hope of success (and it may still be so) but I wanted to see if there was enough space, so I made a template based on the existing socket hole and tried to fit it within the available space. While I did this, I could not help thinking that Collins may have allocated enough space for that same reason when they designed and built the 30S-1.

Luckily I happen to have a spare 30S-1 with some missing parts, allowing me to play with.

There is enough room for an extra filament transformer or a single 6V 20A one. It is amazing how much progress has been made in fans and how small they now are compared to the original squirrel cage originally installed.

Grids may have to be wired separately, unless the tubes are perfectly matched; in this case there will be two bias circuits so that each plate idling current can be properly set. This will require also switching PA plate current readings for each tube.

The cathodes will be wired together, and also the filaments, requiring 6.0V 20A.